Find out more about our extensive range of services here. Our high quality standards and commitment guarantee the best products and results, not to mention adherence to deadlines and reliability. Do you have any questions, need a quote or want to make an appointment? Get in contact with us.

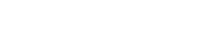

Innovative technology – highest quality standards

WHAT WE OFFER

- Diameter from 3 mm to 650 mm

- Length up to 3,000 mm

- Unit weight up to 2,000 kg

Are you still involved in the planning phase for a new product? We would be happy to pass on our in-depth knowledge of processing technology. It goes without saying that the customised manufacturing of sample parts is also one of our services.

We are your first port of call when it comes to manufacturing individual parts. We also machine customised parts in line with your requirements. Get in touch with us today.

We manufacture series of all sizes with ease, from series with small volumes and few parts all the way through to series of over 20,000 units. With more than 50 processing machines, we ensure high quality and short throughput times.

- Heat treatment

- Galvanised surfaces

- Anodising

- Powder coating

- Glass-bead blasting

- Surface grinding

- Coating

- Barrel finishing

- Electropolishing

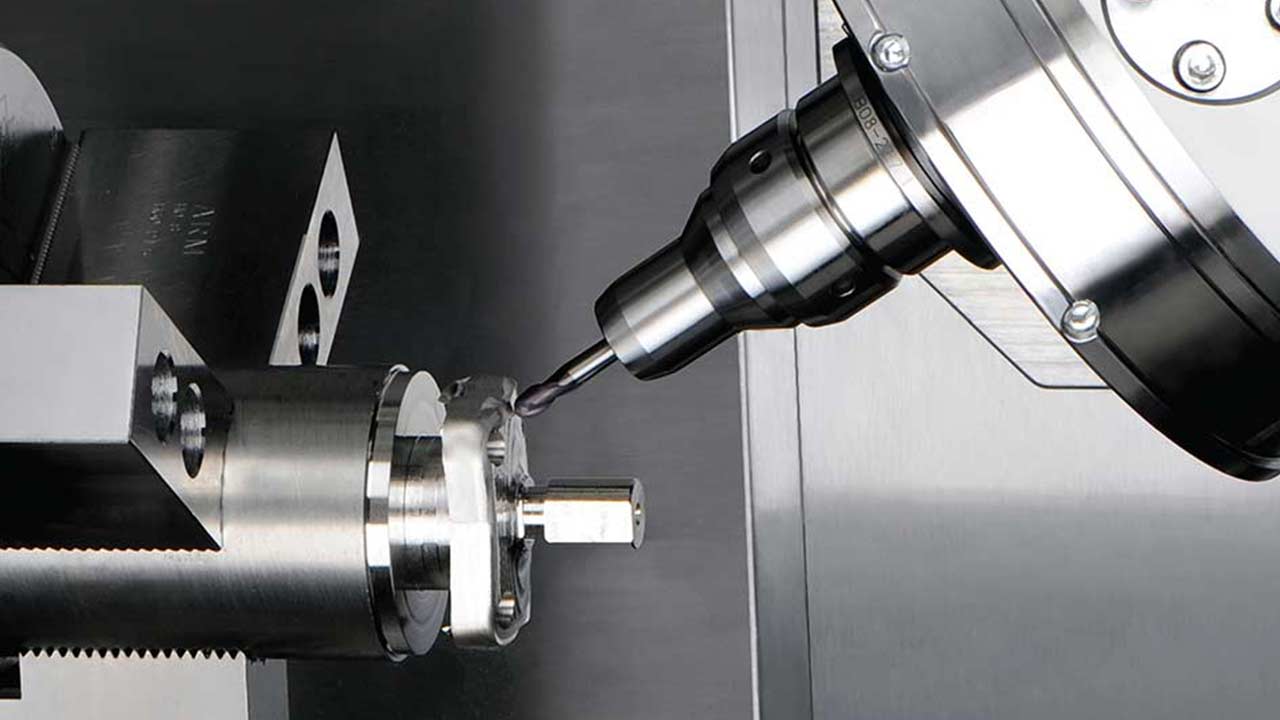

With a total of 21 turning centres and 5 turning/milling centres, we are able to handle the following:

- Chuck parts up to Ø 600 mm

- Shafts up to 800 mm in length

- Rod parts up to Ø 60 mm

- Handling parts up to Ø 150 mm

- 4 x Mazak QT, with X, Z + C axis, Ø 150 mm

- 1 x Mazak QT, with X, Z + C axis, Ø 200 mm

- 1 x Mazak Multiplex, with X, Z + C axis, with robot, Ø 200 mm

- 7 x Mazak QT, with X, Z + C axis, Ø 220 mm

- 1 x Mazak QT, with X, Z + C axis, Ø 250 mm

- 1 x Mazak QT, with X, Z + C axis, Ø 380 mm

- 1 x Mazak QT, with X, Z + C axis, Ø 400 mm

- 1 x Mazak QT, with X, Z + C axis, Ø 450 mm

- 3 x Gildemeister CTX 400, 2-axis, Ø 220 mm

With a total of 11 CNC milling centres, we are able to handle the following:

- Travel distances up to 800 mm x 500 mm x 500 mm

- Horizontal machining centres with pallet changer

- Vertical machining centres with pallet changer

- 5-axis simultaneous machining

Turning/milling centres:

- 1 x Mazak Integrex, Ø 200 mm

- 1 x Mazak Integrex with gantry loader, Ø 200 mm

- 1 x Mazak Integrex, Ø 250 mm

- 1 x Mazak Integrex, Ø 500 mm

- 1 x Mazak Integrex, Ø 500 mm

Milling centres:

- 1 x Mikron VE500, vertical, 4-axis, table, 900 x 300

- 1 x Deckel FP4 CCT, vertical & horizontal, 4-axis, rotary table Ø 500 mm

- 1 x Deckel FP5 CCT, vertical & horizontal, 5-axis, rotary table Ø 500 mm

- 5 x Mazak, vertical, 3-axis, for tables from 900 x 410 to 1800 x 655

- 1 x Mazak, vertical, 4-axis

- 2 x rotary table Ø 630 mm, height 900

- 2 x Mazak, vertical, 5-axis

- 2 x rotary table Ø 500 mm

With a total of 8 conventional lathes, we are able to handle the following:

- Conv. lathes, ø = 650 mm, length = 3,000 mm

- Conv. radial drill

- Conv. line drill

- NC-controlled tool milling machine

- Surface grinding and cylindrical grinding machines

With a total of 5 grinding machines, we offer the following processing options:

- Cylindrical grinding (internal / external)

- Surface grinding

- Tempering in the annealing oven

We offer all conventional welding methods, which are carried out by TÜV-certified welders.

- Lorch WIG welding machine 240 A

- Lorch WIG welding machine 270 A

- Lorch MAG welding machine 300 A

- Lorch WIG welding machine 300 A with rotary table and NC control

- Helium leak tester

- Lorch WIG welding machine V50 DC

In order to improve production runs at Metalltechnik, a computer-controlled high-bay cassette storage system was commissioned in 2009 with surrounding storage areas for rod material of up to 4 metres. Our materials warehouse features the following:

- 244 storage positions

- More than 40 material types

- Around 100 tons of raw materials in stock constantly

- Round material ø 10 to 400 in stock in common materials

- Special materials (alloys) in stock in various sizes

- Kasto cassette storage system

- 4 x Kasto band saws ø 260 mm

- 1 x KastoTec AC4 band saw ø 430 mm

- 1 x Kaltenbach circular saw ø 70 mm

The range of stainless steel grades in stock at our warehouse ensures a high level of availability and great flexibility as a result. Our material handling system is TÜV-certified.

- (1 x with horizontally controlled dividing head, 4-axis)

- Standard testing equipment (callipers, micrometers, etc.)

- Around 400 thread gauges (various special threads)

- Hommel surface measuring devices (Ra testers)

- Optacom conturograph with LC-10 surface module

- Zeiss Contura CMM

- Fischer FE tester

- Spectro PMI tester

- Schilling marker (surface etching)

- Propen markers

- Trumpf lasers